Mechanical Lifting Hazards – 12 Modules | One Day USD: 150/- and Two Day USD: 250/- Per Pax.

Description

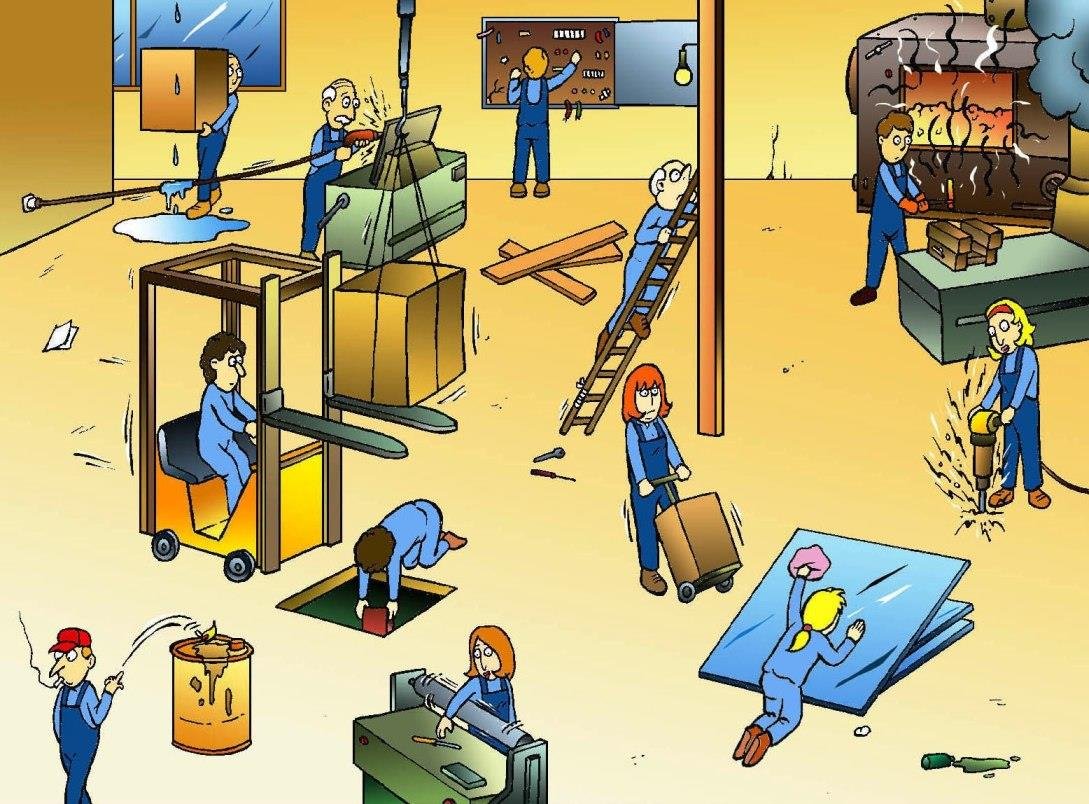

Module 1: Introduction to Mechanical Lifting Safety

- Definition and importance of safe lifting operations

- Overview of lifting hazards in the workplace

- Regulatory requirements (OSHA, LOLER, ISO standards)

Module 2: Types of Mechanical Lifting Equipment

- Cranes, hoists, forklifts, chain blocks, slings, shackles

- Mobile vs. fixed lifting devices

- Equipment selection and suitability

Module 3: Understanding Lifting Hazards

- Overloading and equipment failure

- Load shifting, swinging, and dropping

- Pinch points, entanglement, and struck-by hazards

Module 4: Risk Assessment for Lifting Operations

- Identifying lifting-related hazards

- Assessing risk levels (weight, distance, conditions)

- Implementing effective control measures

Module 5: Lifting Plans and Safe Systems of Work

- Purpose and components of a lifting plan

- Pre-lift meetings and communication

- Role of lift supervisor, signaler, and operator

Module 6: Load Characteristics and Stability

- Center of gravity and balance principles

- Safe rigging and slinging methods

- Tag lines and load control techniques

Module 7: Inspection of Lifting Equipment

- Pre-use and periodic inspections

- Criteria for rejecting defective equipment

- Maintaining inspection records and tagging

Module 8: Safe Use of Slings and Accessories

- Types of slings (wire rope, chain, synthetic)

- Correct sling angles and load distribution

- Avoiding twists, knots, and shock loading

Module 9: Operator Competency and Responsibilities

- Qualification and training of lifting operators

- Safe operating procedures

- Coordination and clear communication signals

Module 10: Environmental and Site Conditions

- Wind, lighting, surface, and ground stability

- Working near overhead power lines and confined spaces

- Emergency preparedness for adverse conditions

Module 11: Accident Prevention and Emergency Response

- Common causes of lifting incidents

- Steps to take in case of mechanical failure or dropped load

- Reporting, investigation, and corrective actions

Module 12: Continuous Improvement and Safety Culture

- Lessons learned from lifting incidents

- Regular training and competency refreshers

- Promoting teamwork and proactive hazard reporting

View more Courses

Hi, Welcome back!