Manual Handling and Ergonomics – 12 Modules | One Day USD: 150/- and Two Day USD: 250/- Per Pax.

Description

Module 1: Introduction to Manual Handling and Ergonomics

- Definition and importance of safe manual handling

- Relationship between ergonomics and worker health

- Legal requirements (OSHA, ISO 11228, EU Manual Handling Directive)

Module 2: Understanding Manual Handling Hazards

- Common causes of manual handling injuries

- Back strains, muscle fatigue, and repetitive motion injuries

- Environmental and task-related factors

Module 3: Anatomy of the Spine and Body Mechanics

- Basic structure and function of the spine and muscles

- How poor posture causes injury

- Importance of natural alignment during lifting

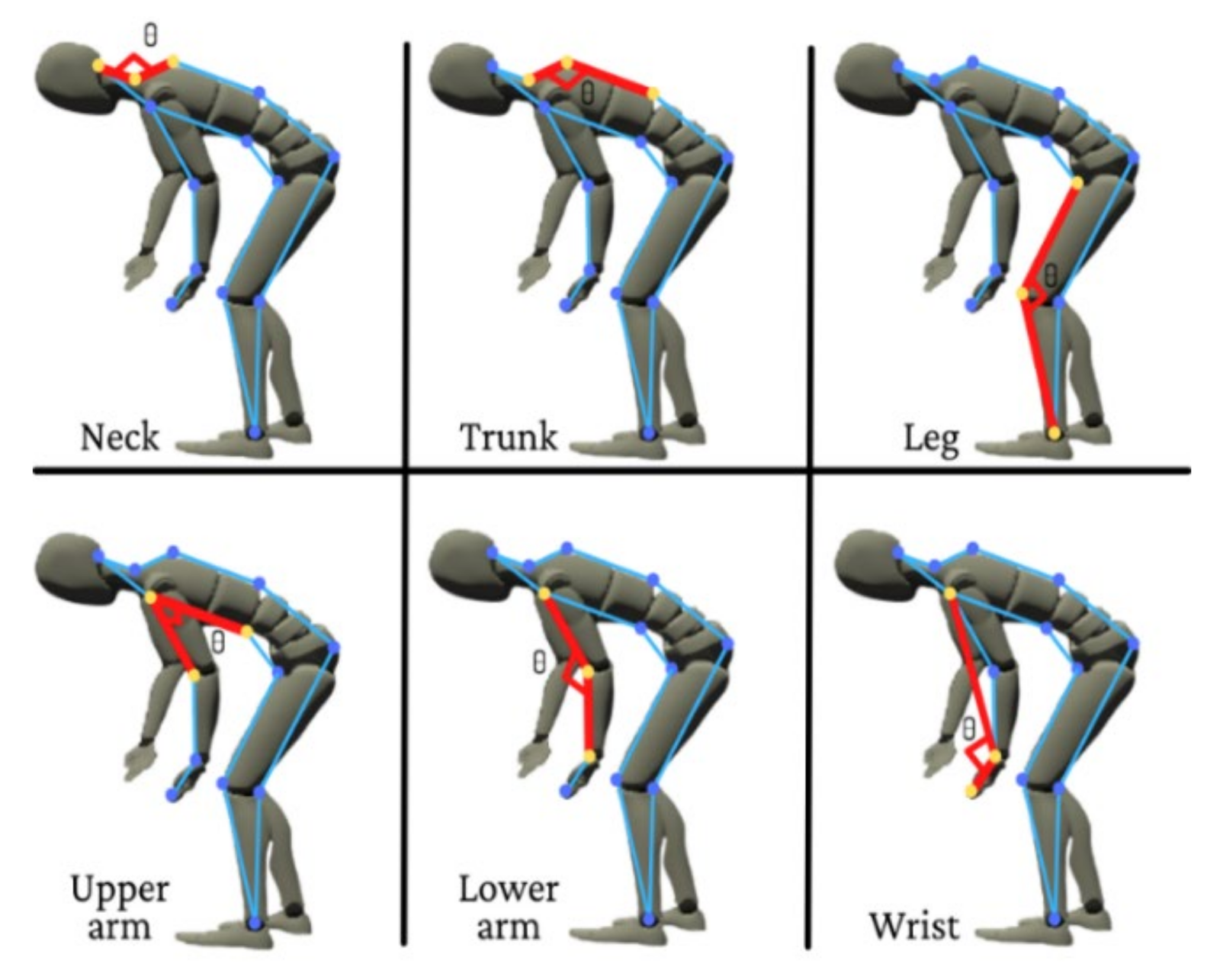

Module 4: Risk Assessment for Manual Handling Tasks

- Identifying hazardous lifting tasks

- Assessing load weight, frequency, and posture

- Using manual handling risk assessment tools (TILE: Task, Individual, Load, Environment)

Module 5: Principles of Safe Lifting and Carrying

- Step-by-step guide to proper lifting technique

- Team lifting and use of aids

- Avoiding twisting, jerking, or overreaching movements

Module 6: Ergonomics in the Workplace

- Ergonomic design of workstations, tools, and equipment

- Adjusting height, reach, and visibility for comfort

- Reducing repetitive strain and awkward positions

Module 7: Use of Mechanical Aids and Equipment

- Types of aids: trolleys, hoists, conveyors, pallet jacks

- Safe handling and inspection of aids

- Choosing the right equipment for the job

Module 8: Work Environment Factors

- Lighting, temperature, and space considerations

- Slippery surfaces and trip hazards

- Impact of noise and distractions on safety

Module 9: Training and Competency Requirements

- Worker and supervisor responsibilities

- Periodic training and refresher programs

- Promoting awareness of ergonomic hazards

Module 10: Incident Prevention and Response

- Recognizing early symptoms of musculoskeletal injuries

- Reporting procedures for manual handling incidents

- First aid and medical management for back injuries

Module 11: Continuous Improvement and Ergonomic Assessment

- Regular ergonomic evaluations of workplaces

- Feedback systems for improving design and practices

- Integration with safety management systems

Module 12: Building a Culture of Safe Manual Handling

- Encouraging worker participation and ownership

- Good housekeeping and layout for easy movement

- Recognition and reinforcement of safe behaviors

View more Courses

Hi, Welcome back!